On Monday, I visited a foundry on Mare Street in Hackney. I showed up at 6.30am in rain! The dedication!! As I plead my case the first question I am asked is: You know it is very physical job? EW! The prejudice. But it is fine, because I also judged them! I didn’t like it there. The men in the workshops were stereotypically manly. I assume they wouldn’t have the care and patience that James has.

I do tell James about visiting other workshops. However, he wants me to stay at Flux. It feels nice. I think I will hold on and stay. I love it there.

A quick job of plasma cutting oil barrels! I had to add an internal structure and wheels. They will put fake fire in them. COOL! The drawings they sent us were drawn with a finger on a phone! CRAZY! So again, there was miscommunication and I had to edit it :/

I finished them all on Tuesday.

On Wednesday, James showed me how to weld aluminium! It is FUCKING HARD and annoying! The process is quite different. The welding machines have different settings specifically for aluminium! On that day, I had to make an A-board café sign. I cut the sheets of metal and bent them, but I wasn’t ready to weld it. James welded the hinges I made for it myself!

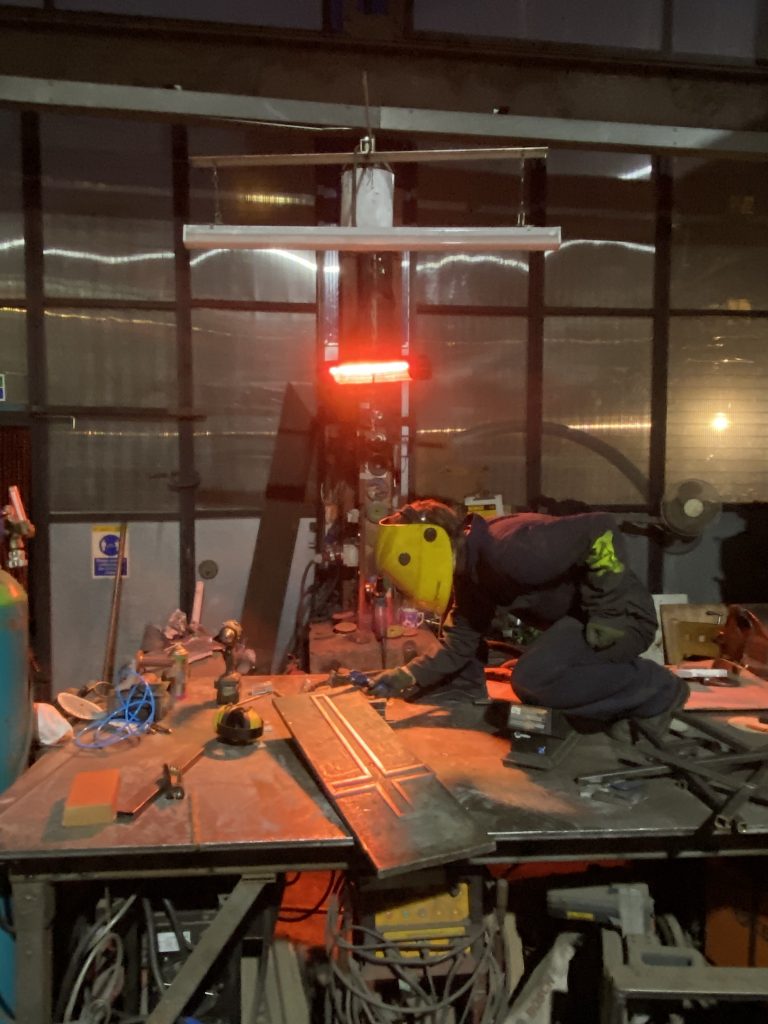

The next day, I had another aluminium job and I worked on it completely alone! WOW! I fucked up a couple of times, but I fixed all my mistakes, so the job took me forever and I couldn’t finish it! Damn it!

Next week I’ll be in Poland for my grandma’s 75th birthday! WEEEE!

I will only see a picture of it :c

It was a cross — like the one Jesus was crucified on. It gave me an idea for silly pictures, which James took of me at the end of the shift.

Another person I appreciate there is Charlie! He is very technical and proper. I like it. He seems to care that I do well. He teaches me a lot, too. Dude is only one year older than me! Shocking! I aspire to be like him as well!